1.Best CNC Machining Services China

CNCchinese provides different CNC machining services including CNC turning Services, CNC Milling Services and wire EDM, and surface grinding. With our precision CNC machining, together with other technological capabilities and experienced team, we can handle every technical aspect of creating your parts prototypes, so you can only focus on sending your product to market.

If you need a company well-versed in providing precision CNC machining services for metal and plastic CNC machining parts, CNCchinese is the way to go. Contact us to get your manufacturing details and solution.

CNCchinese’s highly-vetted overseas network of CNC machining suppliers makes high-quality parts to spec and can meet a range of budget and lead time needs. Our US-based team handles the communication with the Chinese facility and fully manages your order from quote to delivery. If you want domestic CNC machining, we have that as an option as well. Simply specify the geography you want on the quoting form.

CNC Services offered in China include:

ISO 9001 and ISO 13485 registered facilities

Milling, turning, lathe, grinding, and routing

3-axis, 4-axis, and 5-axis options are available

Small and large parts

We help you navigate the complexities of CNC machining in China. Our skilled team of engineers:

Understands your end-use (prototype, saleable, low to high volume) and helps identify the right manufacturing solution

Works with you to find the right Chinese supplier based on your unique needs

Manages all communication with the overseas supplier so you don’t have to. We have team members on the ground in China to help manage your project

For an instant quote and design-for-manufacturability feedback, please upload your CAD file. We want to earn your business. If you get a lower CNC machining quote, send it to us and we will try to beat it.

2.What is CNC Machining?

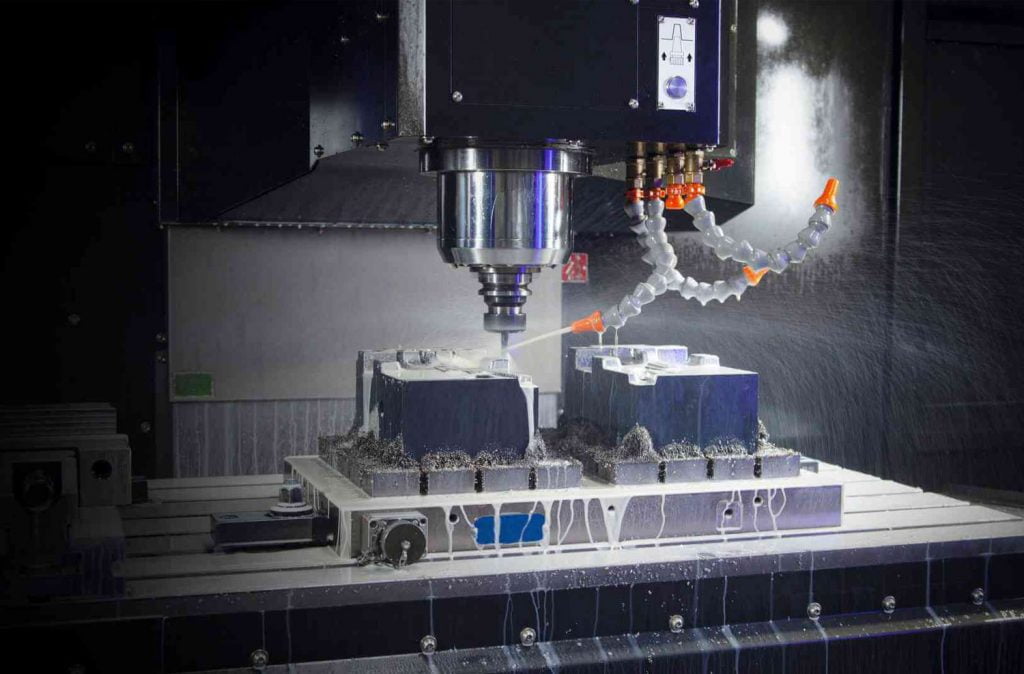

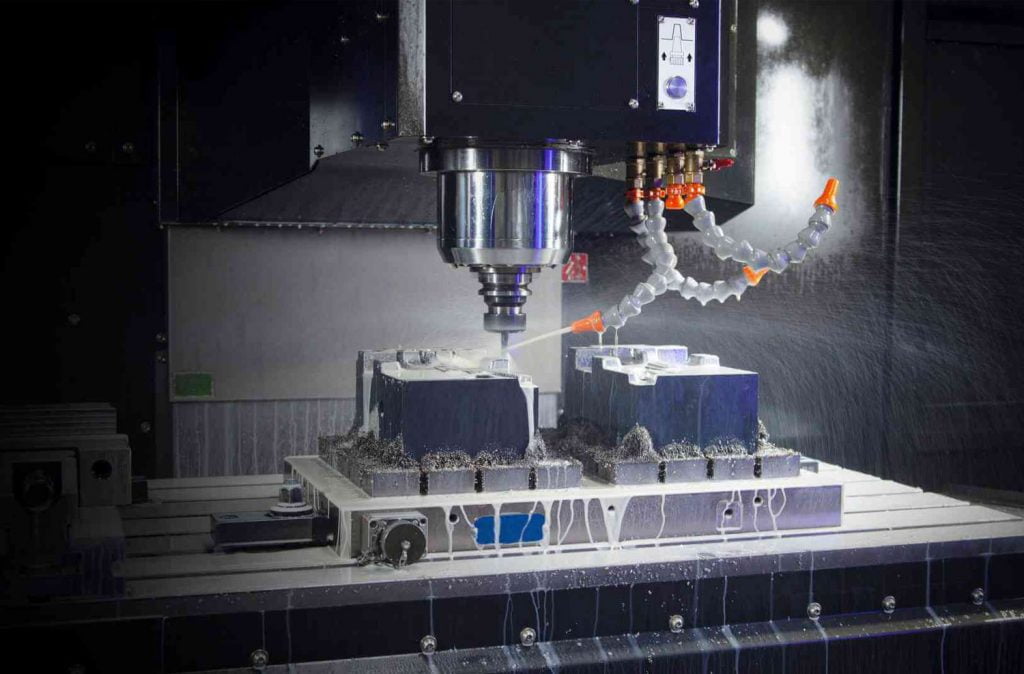

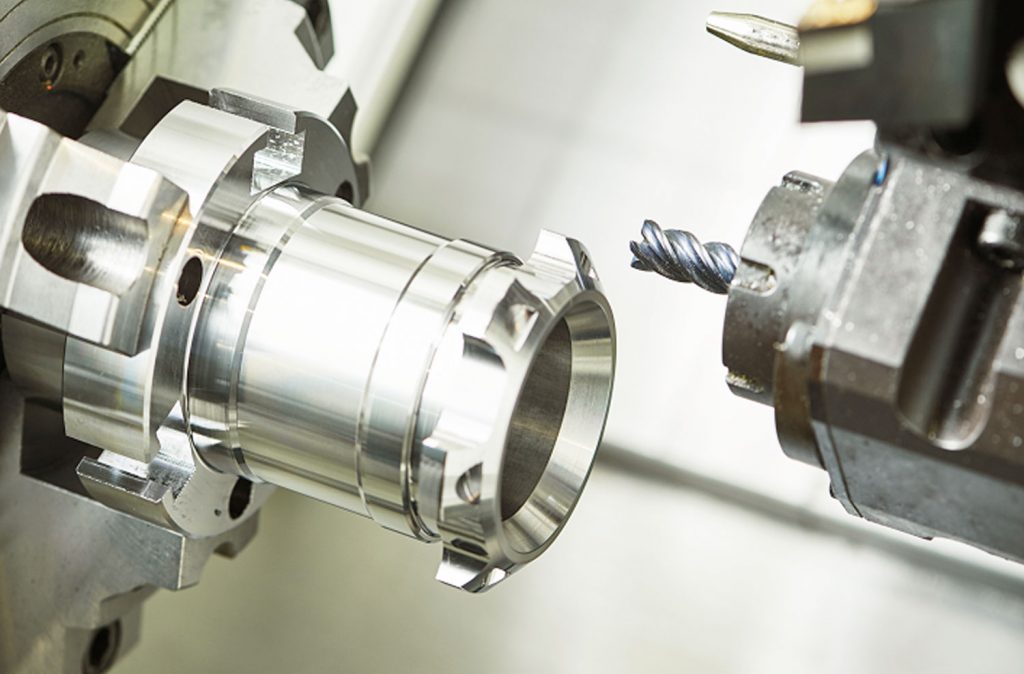

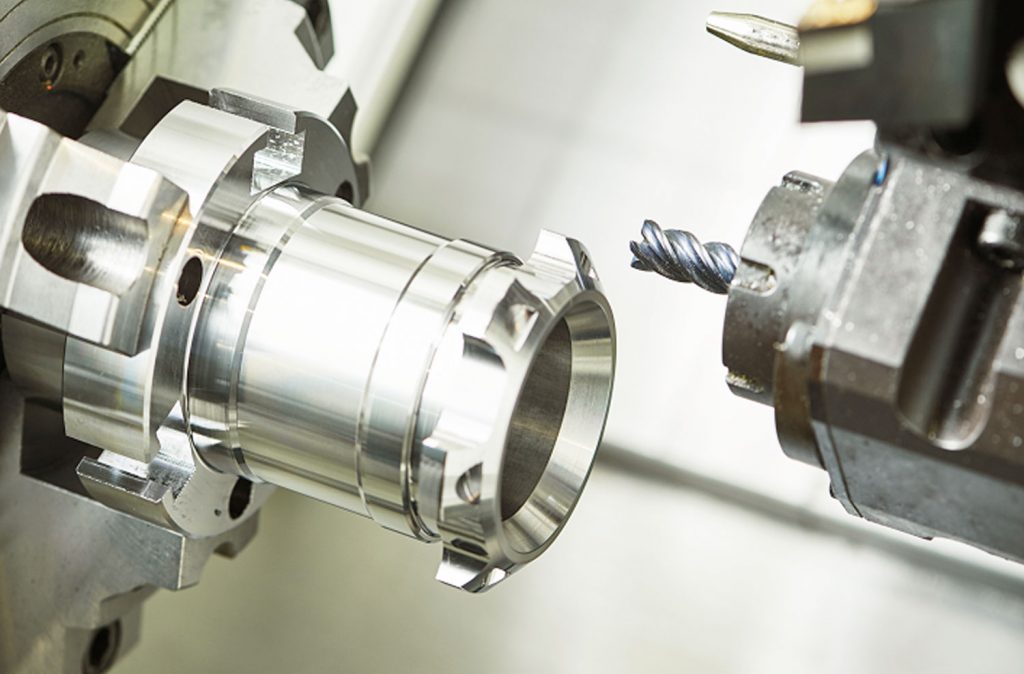

CNC Machining Services

As compared to CNC turning service, CNC milling Services, especially 5-axis milling is used to create difficult 3D shapes or for the application of machined features to parts made; both metals and plastics. The benefit of multi-axis milling machines makes the process of CNC milling versatile, accurate and repeatable, for making many types of part features of complex geometries. These include curves, slots, holes, shapes, angled, and channels. Milling is ideal for creating tooling for plastic injection molding and pressure die casting.

CNC Turning Services

CNC lathe machine allows us to obtain high-speed CNC turning of both metals and plastics from block or bar material. Our CNC turning services allow you the production of complex internal and external geometries, including creating all types of threads. For every component, which is round-shaped, for example, worms, spheres, shafts; CNC turning is an efficient technique compared to CNC milling Services. CNCchinese’s capacity of providing CNC turning services can make prototypes all the way through mass production parts.

3.High Precision CNC Machined Parts

CNC machines can create a broad range of features and high-precision parts. For instance, CNC milling machines are ideal for producing cavities, angled shapes, holes, and slots.

In contrast, CNC lathes are suitable for creating cylindrical shapes or parts that are symmetrical near their axis.

Nevertheless, CNC milling and turning machines can achieve tolerances as tight as ±0.001mm.

They are also compatible with a broad range of materials, including metals and plastics, so long as these materials are available in blocks. This is not the case with additive manufacturing technologies (like 3D printing), which are only compatible with plastics and a few metals.

4.Advantages of Gensun’s Services

#1 High-quality and reliable

We have highly trained engineers, machinists, and quality control experts capable of getting your product done right the first time. Our team of experts follows industry standards by using best-in-class software, state-of-the-art CNC technologies, and quality control tools to create customers’ parts.

#2 Broad range of material options

We offer a wide range of material options, including metal parts (like aluminum, steel, stainless steel, brass, copper), plastic parts (like POM, PTFE, PC, PEEK, PET), and special alloys (like Kovar, Invar, Inconel, Titanium, Mocu).

#3 World-class machine shop

We adhere strictly to several key industrial, quality, and environmental standards. For instance, our machine shop is ISO 9001:2015 certified for quality management systems, ISO 14001:2015 for environmental management systems, and ISO 13485:2016 certified to fabricate medical devices.

#4 Cost-effective manufacturing services

At Gensun, we adhere strictly to the design for manufacturing (DFM) criteriaㅡwhich means we design parts and optimize designs for ease of manufacturing. This reduces our start-up, material, and feature costs, providing you with a cost-effective manufacturing service.

#5 Fast manufacturing and delivery

Not only do we get your products done right, but we are also located in southern China’s Greater Bay Area. We’re close to major shipping ports, allowing us to get your products to you swiftly.

#6 Custom CNC machining

We offer custom CNC machining services to our customers that want to replace obsolete parts, work with difficult materials, or manufacture parts with special requirements.

What are the benefits of CNC machining services in China?

CNC machining services in China have several benefits for you. First, the supply chain is very broad and efficient. Next, our operators are skilled and motivated. And yet, they work 10 hours per day. Do you think the distance is a disadvantage? Well, we deliver small series to Europe within one week, if requested. This is including sand blasting, anodizing and laser engraving of text and symbols, for example. But, don’t try to speed up too often. Because, fast fabrication comes at an extra cost and you might penalize the quality.

Lets say an average production time for small series is about 3 weeks. At Davantech we are good at manufacturing custom machined parts. More specific, CNC milling of aluminum and other materials like stainless steel and brass and common steel are among the possibilities. In addition, we fabricate plastic components.

You can count on our high standard and prices are competitive. Don’t hesitate to drop us an email with your inquiry. One of our sales engineers will answer you request within 24 hours. And not to forget, we offer CAD services and engineering support as well. When you let us make the drawings you can rest assured the parts will be designed and manufactured in the best possible way.

5.Our China CNC Machining Services

CNC milling service.

CNC milling is one of the CNC machining services we offer. More specific, we fabricate parts in China with high precision. Ask a quote for a trial order. You might think the cnc machining process looks similar to drilling, however, the two manufacturing process are definitely not the same. Drilling is only suitable for axial processing. Other axial cutting processes are making holes, tapping of tread and reaming. A CNC mill moves laterally and axially to remove material. There are different types of milling tools, each used to make specific cavities or just cut away material. Axial cutting requires teeth on the tip of the cutting head. At Davantech we work with the latest machinery. These include 3 and 5-axis milling equipment. Manufacturing of precision components with an outstanding surface finish is possible with our CNC machining capabilities.

CNC turning service: precision machining.

With our CNC turning services we offer precision turning. To clarify, both plastics and metals are cut to the desired shape with the highest accuracy. Davantech is one of the most capable sources for CNC turning in the Dongguan area. Furthermore, we get the job done correctly and at an competitive cost.

Our equipment to fabricate machining parts.

We operate all necessary equipment for milling with high precision and as such we produce high quality metal and plastic parts. There is a strict follow up of the machines tolerances and we adjust when necessary. Two high skilled programmers make the CAM programs for numerous machining parts, every day. In addition, quality engineers follow the first out-of-machine samples to inspect and adjust on the spot.

- We have many 3- and 4- axis CNC milling centers.

- 5-axis CNC machining centers.

- Milling centerss to mill large parts up to 4 meters in length.

- CNC turning lathes

- Conventional turning and milling equipment.

- Drilling of holes an deburring.

- Tapping of threaded holes.

- Reaming of holes with narrow tolerances.

6.Applications of CNC Machining

Design & Rapid Prototyping

The machinability of numerous evaluations of titanium and treated steel makes CNC machining a generally utilized cycle in medical services, with the interaction routinely used to make inserts, clinical gadgets, and careful devices like surgical blades.

Tight tolerances and quick turnarounds are particularly significant for things like titanium hip inserts, which ought to be custom-fitted to a patient’s life systems.

Mold Making

EDM and CNC machining are primary techniques to fabricate metal tooling for molding, injection high pressure dies casting, roller molding, blow molding, stamping, and blending, and so on.

Rapid CNC machines permit us to make high-precision copper designs, shape cavities, form base, lifter, and other form parts in the extremely present moment. Also, with 5-axis processing machines, we can process the profound pocket highlights in hours which require days to make by EDM previously. That is the way we can speed up the shape-making measure significantly.

Aerospace

CNC machining contains several years been a key part of aerospace manufacturing. That’s slightly down to the high precision of CNC machines, making the whole process suitable for safety-crucial parts that are used on aircraft.

Machinable aviation parts incorporate model motor segments, fuel boards, landing gear segments, and motor mounts.

Automotive

In this industry, CNC machining is among the popular ways to make concept cars as well as the function testing parts, such as the engine, lighting, steering, and transmission system. It is also used to make high-volume post-machining and automotive parts the die casting parts, investment casting parts.

It is particularly helpful for custom car parts, which might be needed for fixes or restricted version luxury vehicles since it is too expensive to even think about making not many parts by trim cycle.

Medical

The machinability of numerous evaluations of titanium and treated steel makes CNC machining a generally utilized cycle in medical services, with the interaction routinely used to make inserts, clinical gadgets, and careful devices like surgical blades.

Tight tolerances and quick turnarounds are particularly significant for things like titanium hip inserts, which ought to be custom-fitted to a patient’s life systems.

Consumer Products

Even though infusion shaping rules the creation of straightforward plastic parts, numerous off-the-rack products are made with CNC machining.

Family products and apparatuses regularly contain machined parts, while things like nooks and installations are additionally appropriate for the interaction. Merchandise such as sporting gear may likewise be CNC machined.

The CNC machining of metal and plastic segments assumes a major part in the hardware business. Things like PC housings, connectors, and attachments would all be able to be dependably made with a CNC machine.

7.CNC Machining Services Tolerances

With a broad range of CNC machines, we can provide standard-tolerance CNC machined parts within the economic price and super precision machined parts for all high-end products. When working with CNCchinese, we guarantee your specification will be taken care of.

Precision CNC Machining

CNCchinese also offers high-quality precision machining service. Along with high precision turning and milling machines, we have the capacity of catching super tight tolerance for prototype production and machining.

Being in the CNC industry for over a decade, we have discovered a simple formula to offer precision machining service

Precision machines + Precision heart = Precision parts.

We have a wide range of CNC machines and seasoned engineers who never compromise with part or tolerance quality.

8.CNC Machining Services Materials & Finishes

If you need to manufacture your parts with CNC machining China, it is vital to know the kind of finishes and materials you can apply to your CNC machined parts. We can also apply all types of finishes to CNC prototype parts and production parts thanks to our surface finishing partners. Need custom CNC parts with a high-quality appearance? We are here to help.

CNC Materials

Plastic: HDPE, PS, PAGF30, POM, DHPE, ABS, PP, PPS, (Acrylic), PCGF30, Teflon, PC, ABS+PC, PEEK, PMMA.

Metal: Steel, Aluminum, Stainless Steel (17-4, Inconel 625 & 718), Titanium, Zinc, Magnesium, Bronze, Brass, Copper.

These are rated as the common materials for CNC production parts and prototyping. Besides, we work with all types of machinable metal and plastic and we can buy from the stock market. We source the materials you request in case they are not available in stock. Also, we deliver all machined parts conform your 3D files and technical drawings, since we strive to optimum quality. In addition, we keep an eye on tapping threaded holes, reaming and applying chamfers.

What’s more: We can create customized plastic blocks or bars for the material like PPS GF50and PA GF50. To know further plastic materials, contact our team.

CNC Finishes

As-Machined: The most cost-efficient and popular way for inner operational components. Even and fine tool path is good too, for aspect parts.

Bead Blasted: The part is left with matt appearances. A range of 320 to 120 beads allows us to make different roughness to the surface.

Anodized: Type II makes an abrasion-resistant finish. Parts can be anodized in multiple colors— black, red, clear, and blue are most common. It is typically associated with aluminum’s low silicon element series.

Type III is comparatively thick and generates a layer of wear-resistant besides the corrosion resistance seen with Type II.

Powder Coat: This is a procedure where powdered paint is splashed onto a section which is then prepared in a broiler. This makes a solid, wear-and-consumption safe layer that is tougher than standard painting strategies. A wide assortment of shadings is accessible to make the ideal tasteful.

9.CNC Machining Quality Assurance

We take our QA/QC process very seriously at CNCchinese. We wish to provide our clients with the highest possible quality components and products, and our painstaking QA/QC process ensures that your parts meet all of your engineering specifications.

- Our staff of quality assurance (QA) and quality control (QC) professionals are highly-trained and educated, and familiar with all of the latest industry-standard best practices.

- Our testing lab meets all required ISO standards and other qualifications, and we use only the most advanced technology to examine your components and check for quality issues.

- From digital inspections of your CAD files to ICQ inspections and batch inspections and even material inspections, we ensure maximum quality throughout every step of the manufacturing process.

- Each batch products you receive will include a standard report outlining tolerances, specifications and other such information. We also offer optional dimensional inspection reports and material reports.

10.How to choose the right CNC machine shop in China?

So far, I believe that you’ve grown some interest in finding a CNC machining service in China, I mean, at least take a try, request a quote to see the price. Well, below are a number of important factors that can help you and your business find the right CNC machining partner in China.

a. Certifications

When exploring outsourcing options for rapid prototyping and production, one of the most important things in choosing a manufacturing partner is checking their certifications to see if they align with the type of product you are seeking to produce. If, for instance, a customer is ordering a part for the medical industry, the CNC machine shop should have the appropriate certifications and stringent quality control processes needed for the healthcare industry.

b. Quality control

In a similar vein, it is important to establish what quality control equipment and processes a CNC machining service offers, including raw material inspection, in-process quality checks, finished part inspection and outgoing quality control. A CNC machining company that provides a comprehensive and state-of-the-art quality control workflow will ensure that your prototypes and products are up to the highest standard.

c. Communication

As mentioned above, one of the previous challenges of western companies working with China-based rapid prototyping and manufacturing companies has been communication. And though the internet has made it significantly easier for international customers to keep in close contact with Chinese manufacturers, it is still important to establish a good rapport with a company before diving into a manufacturing partnership.

At CNCchinese, for instance, we make sure to speak with our prospective clients to guarantee there is a clear understanding of the project at hand. Additionally, not only will we work transparently with our clients to complete production, but our experts will also help to optimize and improve products and manufacturing where possible.

d. Production capabilities

This next point may seem obvious but is still worth highlighting. If you are searching for a Chinese rapid prototyping company to work with, be sure to check that it has the right equipment and production capabilities to fulfill your order, including CNC milling and turning machines, multi-axis machining systems and more. In addition to production hardware, ensure that the company is familiar with and works with the type of material you require, whether it is metal, plastic or other.

e. Place a small order as trial

Lastly, to ensure that a prospective CNC machining company in China can meet the quality requirements for a specific part or product, it is advisable to first order a prototype of the part. At no big expense to the client, a prototype will enable them to check that a particular CNC machining company is able to produce the part up to certain standards and in good time. At CNCchinese, we guarantee that prototypes are machined and delivered within just three days so that clients can quickly decide to move ahead with an order.

11.Why Choose CNCChinese For Your CNC Services

Why choose CNCchinese as your precision CNC machining and metal fabrication partner? Here are just a few reasons why we’re a cut above the competition.

Comprehensive, all-in-one services

We offer machining solution and surface finishing in a single facility. This helps minimize logistical difficulties, and saves you both time and money

Highest standards of quality

We meet relevant ISO requirements for quality and process control,and our safe, advanced facility is staffed by experienced technicians to ensure the best possible results

Scalable for projects of any size

We offer rapid prototyping for small-batch orders, low-volume production and manufacturing for batches of 100,000+ components, and full-scale manufacturing – no project is too big or too small.

Rapid turnaround times available

CNCchinese offers rush service for select projects, such as urgent prototyping jobs. We can build and send your prototype components anywhere in the world in just a few days.

Advanced, specialized equipment

We use only the most advanced CNC equipment. Not only does this ensure you get the best possible results, but our focus on automation and efficiency means you save money

Experienced and skilled engineers

50+ engineers and desingers, the most specialized and highly-skilled. You can trust our staff to handle your project

12.Frequently Asked Questions About Machining in China

- Will I get finishing certs when my CNC parts are made in China?

- No. CNCChinese does not provide finishing certs for parts that are made in China.

- Is there a quality difference between parts that are made in the US vs parts that are made in China?

- No. All CNCchinese parts will meet the CNCchinese Manufacturing Standards regardless of country of origin.

Does CNCchinese collect duties and tariffs?

- Yes. Duties and tariffs are included in your part price. You are not required to pay any additional fees.

- Does CNCchinese inspect parts from China?

- All parts made in China are manufactured and inspected in accordance with CNCchinese’s Manufacturing Standards and our Inspection & Sampling Plan.

13.What are the Advantages of China’s CNC Machining?

A.Compared with the United States, What are the Advantages of China’s CNC Machining?

China is indispensable in the field of CNC machining services when it is compared to the United States.

No doubt the United States holds a potential marketing place when it comes to CNC machining services, but China still lies on the top because of reliable CNC machining service providers.

CNCchinese is one of the leading suppliers and service providers in China for supporting various industries.

Some other substantial advantages that are available with China are given as under:

- China fulfills all quality standards, including the ISO 9001:2015

- Chinese CNC machining services are 40% faster than other countries

- Chinese CNC machining services will help you save 60-80% on production cost

- China holds many reputable companies for producing CNC related materials

B.Compared With Japan, What are the Advantages of China’s CNC Machining?

CNC machining services in Japan’s various states are worth praising, but they are still under-development when compared to the Chinese CNC machining services:

China leads all CNC machining services providing companies with the availability of worthy manufacturers and suppliers. CNCChinese is also one of these suppliers that steps up the position of China’s CNC machining.

However, the cost-effectiveness, reasonable prices of the services, industry chain concentrations, fast delivery, and many other advantages are associated with China’s CNC machining services.

C.Compared with Germany, What are the Advantages of China’s CNC Machining?

No doubt Germany’s CNC machining services are noteworthy in many manufacturing industries. But if we compare these services with China’s CNC machining services, China always stands out of the list.

The availability of a long list of reliable and friendly manufacturers in China has led people to visit China’s CNC machining service providers on the go.

Besides the availability of many manufacturers, China also offers many other advantages of CNC machining services.

Some of these advantages are:

- Excellent production capacity with 60-80% cost-effectiveness

- Extra-fast delivery as compared to other CNC machining companies

- Compliance with all working and quality standards

- Reduction of the loss risk

D.Compared with Vietnam, What are the Advantages of China’s CNC Machining?

Vietnam holds a reputable place for fulfilling the OEM & ODM services related to CNC machining, but China still leads the market share with its excellent CNC machining services.

The primary reason for China’s leading services in CNC machining is the presence of trustworthy manufacturers.

But there are many other advantages of China’s CNC machining services compared to Vietnam’s services.

Some of these advantages are listed as under:

- Cost-effectiveness

- Fast-delivery of orders

- Maintenance of all quality and safety standards

- Reliable industry chain concentration