Quality Assurance

Deliver quality parts that meet requirements and exceed expectations.

manufacturing standards

Tighter tolerance are examined on a case by case basis with your technical drawings. Contact with gben@cncchinese.com for special requirements.

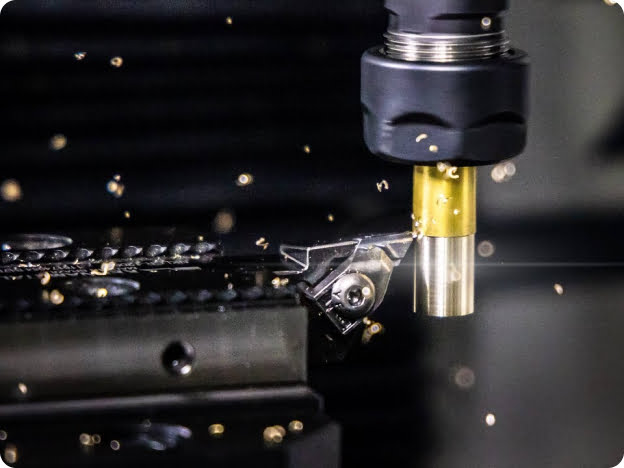

CNC machining standards

CncChinese, provides high tolerance CNC machining processes including 3, 4, 5 axis CNC milling, CNC turning, and post-processing services for your diverse manufacturing requirements.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Smallest thread size available | M1x0,25 |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Smallest thread size available | M1x0,25 |

| Part size limit | 950 * 550 * 480 mm 37.0 * 21.5 * 18.5 inch |

If no 2D drawing is provided, CncChinese produces parts according to ISO 2768 M standard. With 2D drawing, we can reach tolerance as tight as +/- 0.01 mm.

Qualifications

CncChinese shares a continuous growth of 300%+ year-over-year annual growth. These are the features that make us stand out.

Pre-production

Technical assessment

Before the production stage begins, our engineering team performs a technical assessment on your parts design. This includes an assessment on important factors such as material, surface finish, structure, process, and other details of your 3D and 2D drawings.

Material verification

On our customer’s request, we provide a certification of the material we used for making your parts. The report comes from the raw material manufacturer and usually includes: material heat number, material grade, material dimensions, mechanical properties, chemical analysis, etc.

In production

On-site inspection system

In precision machining, it is important that materials being worked on is always at the right position. With on-site inspection system, positions are examined automatically, and adjustments are made accordingly. Using on-site inspection system further helps avoids issues at the early stage, saving cost and time.

In-process quality control

At CncChinese, we strictly obey the ISO9001:2015 requirements. The quality control staff conducts routine inspections for all parts that are being produced every 2 hours. This further prevents risks from happening.

Before delivery inspection

Full-dimensional inspection report

Packaging

Ensuring that the parts we manufacture are of the highest quality is important. We know about the unpredictability of logistics. Therefore, we make sure we lower the risk to the parts during our packaging process. Four layers of protection: 1. wrapping paper 2. EPE 3. foam 4. paper/wooden box are applied during the packaging process, ensuring that we deliver the most high-quality and beautiful parts to you.

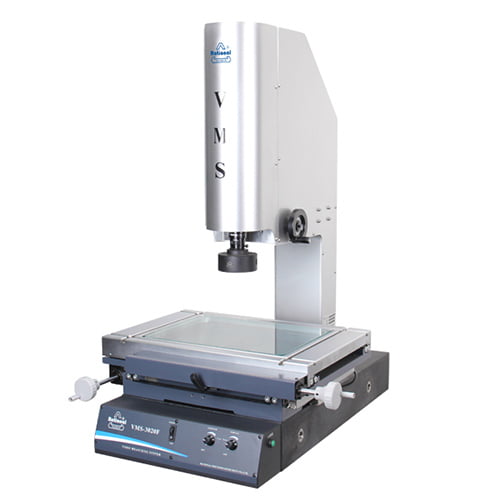

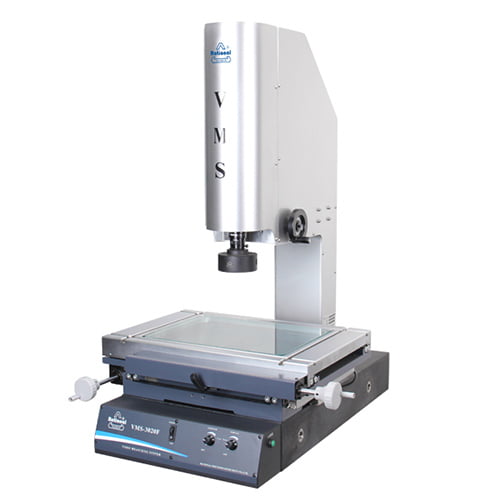

In-house inspection equipment

For all orders, we provide full dimensional inspection report on request. This report will include the following: quantity of parts, critical dimensions, threads and tolerances, thicknesses and depths, part appearance, etc.

Quality reports

For every order on our platform, we can provide a full list of quality reports according to customers’ request. Including but not limited to:

- Inspection report

- Full dimensional report

- Material test report

Certifications

As a decade-experience on-demand manufacturing company, we provide most commonly needed certifications, including but not limited to:

- ISO 9001:2015

- ROHS

- REACH

First article inspection

For low-volume injection molding and CNC machining orders exceed 50 units or 5000 USD in total price, first article inspection is available on request. The process goes like below:

contact gben@cncchinese.com

- The customer request first article inspection for a project that meets our FAI requirements.

- CncChinese reviews on the project and contacts customer for detail information.

- The customer signs the FAI agreement provided by CncChinese and agree on our Terms and Conditions.

- CncChinese produce sample parts according to FAI agreement and deliver to the customer.

- The customer receives and examines the parts, inform CncChinese if full-scale production may begin.

- The full-scale production starts and finishes production within lead time.

Resolving Quality Issues

At CncChinese, it is our aim to deliver high quality parts that matches your requirements and expectations. However, if your order fails to meet your specifications, you will be covered with our Rework and Refund Policy.

Kindly get in touch with us within five business days of receiving your order, and we will resolve the problem rapidly within 1-3 business days.

Conditions for Rework

- Unacceptable processing defects

- Fail to meet tolerance requirement

- Incorrect material / finish

Conditions for Refund

- The part is not machinable

- The customer does not agree to rework

- Other reasons

Preferred Online Prototyping and Manufacturing Services

Hunt Dabney

The 4 parts look great and work very well. This order was to solve a problem on some equipment, so only the 4 parts were needed.

We were very pleased with your quality, cost and delivery, and will certainly order from you in the future. I have also recommended you to friends who own other companies.

- Owner at HDA Technology

Bjorn Steinar Blumenstein

The service at CncChinese is phenomenal and Cherry has assisted us with great patience and understanding.

Great service as well as the product itself, exactly what we asked for and works amazingly. Especially considering the small details we were requesting. Good looking produckt.

- Product Designer at Plasplan

Lars Gerchow

I couldn’t be happier with this order. The quality is as quoted and the lead time was very not only very fast and it was done on schedule.

The service was absolute world-class. Thanks a lot to Linda Dong from the sales team for the outstanding assistance. Also, the contact with the engineer Laser was top-notch.

- Scientist at STEER

Kaushik Bangalore

Hi June, Yes we picked up the product and it looks great!

Thank you for your quick support in getting this done. We will be in contact shortly for future orders